how does vapor honing work

A specially designed high volume pump mixes abrasive media with water. Read customer reviews find best sellers.

Vapor Honing Wet Blasting Vapor Blasting Blast Wash Systems

Vapor honing is a non-aggressive surface preparation method designed for applications that need smoother finishes.

. A very tiny abrasive can be added. Vapor blasting is a non-aggressive surface prep technique that has been specifically developed for applications requiring finer finishes. Weldon-4 solvent gas is sprayed over the surface of the plastic to melt it.

This will also add a small amount of tiny abrasive. Remove machining or directional polish lines or marks on such objects as molds and dies for metal plastics or rubber. In this manner how does Vapour blasting work.

How Does Vapor Honing Work. Vapor honing uses water and abrasive flowing across the surface to scrub away contaminates rather than directly impacting the surface damaging and removing material. This Best Practices Manual is not a standard or regulation and it creates no new legal obligations.

Vapor blasting also known as vapor honing is a blasting process using a mix of water and blasting media such as glass beads or aluminum oxide. How does vapor blasting work. Combining a thin film of water with fine blasting media this technique can remove dirt contaminants rust corrosion and old paint from a wide range of surfaces.

Wet blasting vapor blasting is a process for removing contaminants from a surface or finishing a surface. The second is a pumped slurry with air added to create a more aggressive hone action. Water abrasive and compressed air are 3 ke.

The vapor blasting process provides the highest quality soft surface finish. It also can even remove dirt contaminants rust corrosion anodizing and old paint while gently cleaning the surface leaving a nice. Before you start the cleaning process you need to pick the type of abrasive youll use to clean your part.

Treat the surface to make it metallurgically clean prior to electro-polishing electro-plating or other coating processes. The more proper one is an aspirated water as in a common blast cabinet except it is water instead of grit. Once you concoct your slurry it goes into the sump at the.

Vapor honing is also known as wet blasting it is safe environmentally friendly what vapor honing does is use water and fine high quality abrasives such as glass bead or ceramic powders and air all recycled and reused in our Vapor honing technologys 3630 cabinet. It is commonly used for cleaning aerospace parts and. The biggest benefit like all vapor honing machines offer is the lack of dust surrounding the work area.

Vapor blasting also known as wet blasting liquid honing or dustless blasting is a process that uses pressurized water and abrasive material to remove contaminants corrosion residue or coatings from a surface. Vapor Honing TechnologiesSubscribe to our YouTube Channel. The parts are blasted and photos of the finished work are sent.

This slurry mixture is then sent to a nozzle or nozzles where regulated compressed air is used to adjust the pressure of the slurry as it blasts the. The process was developed in Europe a number of years ago and that might be where the misleading vapor part of the name came from. Vapor polishing is a method for smoothing out certain kinds of plastic resin material at the microscopic level.

How Does It Work. Shorts Like us on FacebookFollow us on InstagramTwitter. But speaking of boiling that is the problem with this design.

Its done by using the volatile gas of Weldon 4 solvent which is highly reactive with the surface chemistry of polycarbonates. Also known as wet abrasive blasting vapor blasting vapor honing dustless blasting or slurry blasting. Vapor honing is one of the most advanced technologies you can use for finishing and cleaning surfaces.

The biggest benefit like all vapor honing machines offer is the lack of dust surrounding the work area. Click to see full answer. This method removes dirt pollutants tarnish rust and old paint from various surfaces by blending a thin layer of water with small blasting particles.

Because of this advantage vapor honing is useful if you work in the auto or motorcycle industries. The Liquid Vapor Honing process is applied to metals for the following reasons. Vapor honing also known as vapor blasting wet blasting or wet honing is a process that mixes an abrasive media with water to create an unparalleled finish and is much gentler on parts than acid baths or sandblasting.

But Did You. Vapor honing does not remove metal its a finish restoration process. Vapor honing has many advantages such as being dust free preserving the surface finish of the part and creating a.

Yes I received on time. It is a non-aggressive surfacing process that provides a high-quality finish even on delicate surfaces. Vapor honed has two common meanings.

What Exactly Is Vapor Honing 5 Things You Should Know

Vapor Hone Up And Running Bike Builds Motocross Forums Message Boards Vital Mx

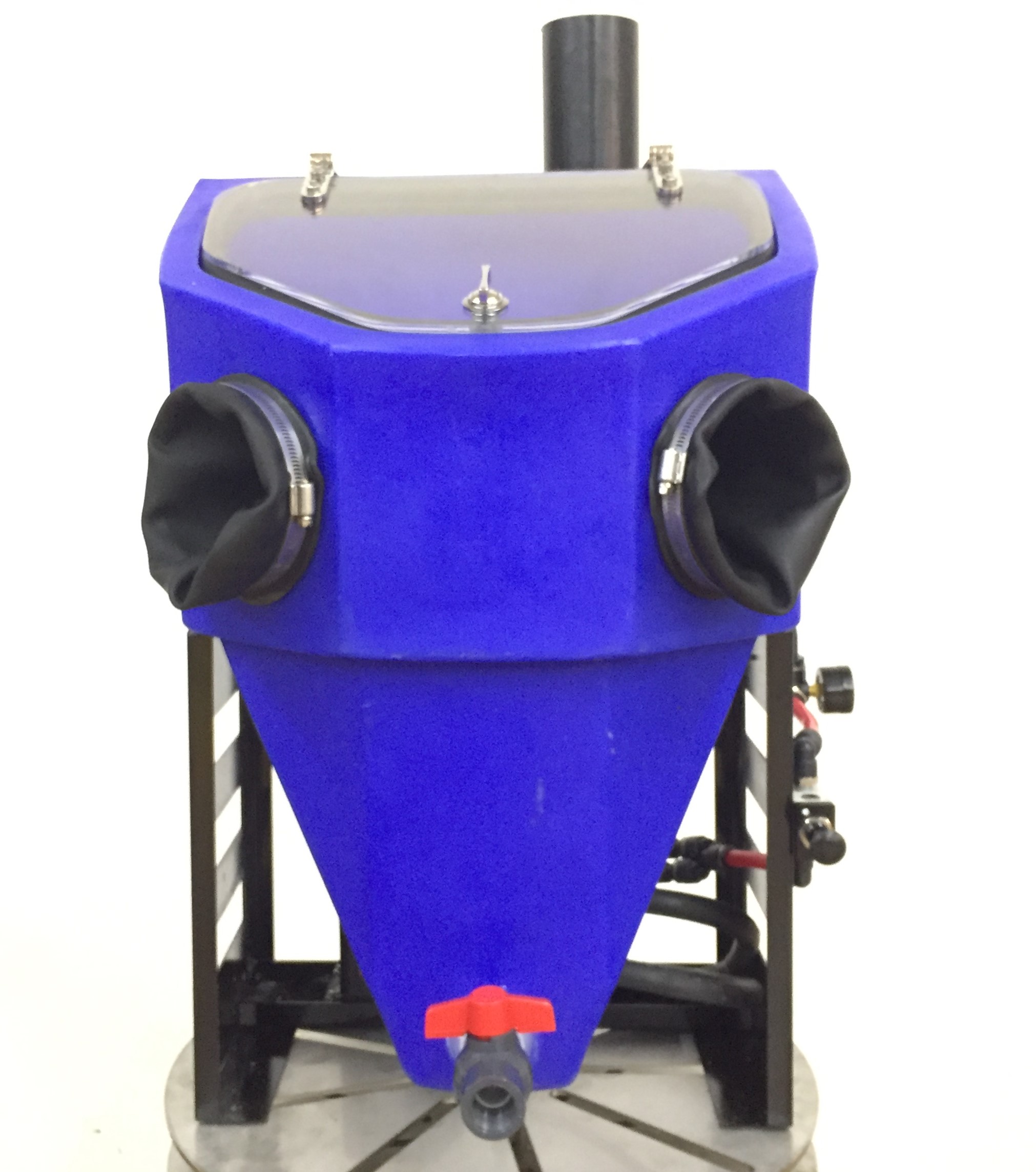

Vapor Hone 1000 Wet Blasting Equipment Wet Cabinet Made In The Usa

Vapor Honing Technologies Honingvapor Twitter

Vapor Honing Technologies Lilhonda Com

Vapor Hone 1200 For Sale Vapor Honing Technologies

Micro Vapor Hone Benchtop Vapor Hone With A Small Footprint

Micro Vapor Hone Vapor Honing Technologies Youtube

A Simple Introduction To Vapor Honing Issuu

Vapor Honing Blasting Superfly Garage

Vapor Honing Services What Is Vapor Honing And Does It Work

Cleaning Pistons Using Vapor Blasting Vapor Honing Technologies Youtube

Micro Vapor Hone Benchtop Vapor Hone With A Small Footprint

Vapor Honing Tuttle Motorsports

Vapor Blasting Services Wet Blasting Vapor Honing Technologies